06 843 8382

e:

steve@intimeengineering.co.nz

Intime Engineering 2016 Ltd

36 Carnegie Street Onekawa, Napier

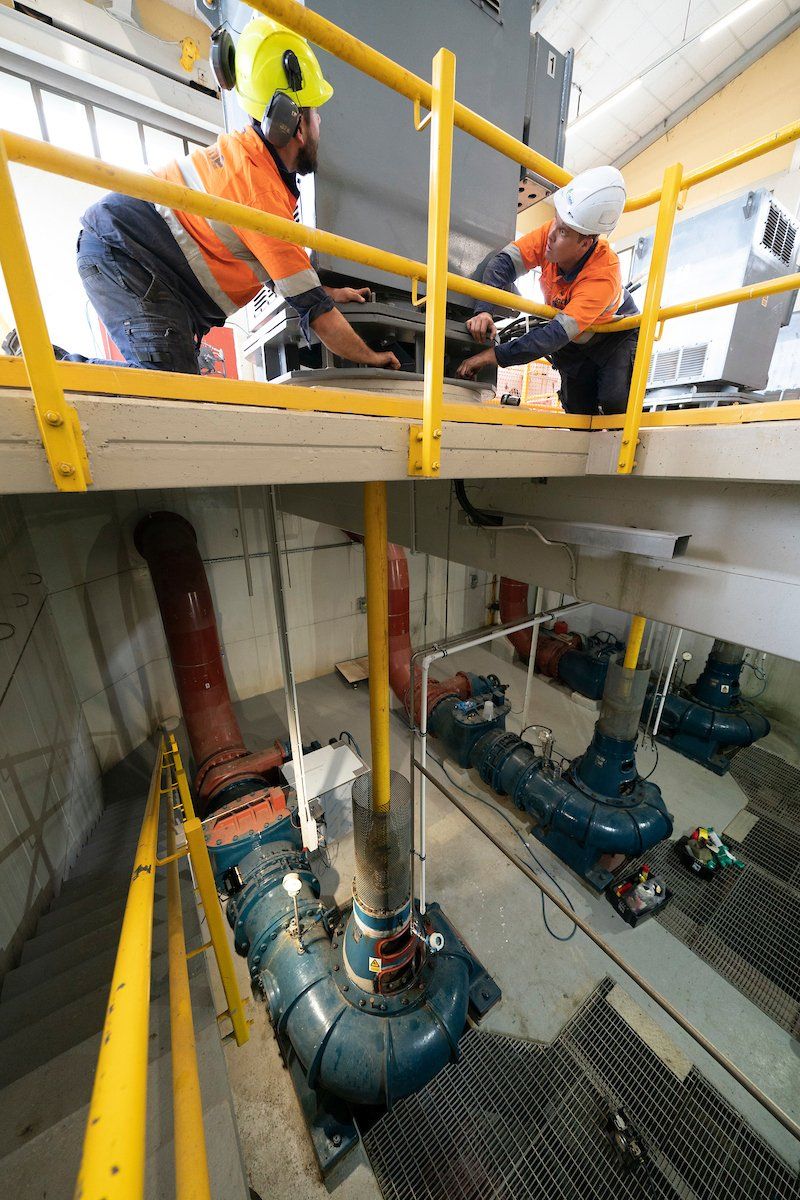

waste water pump maintenance

Follow our engineers as they uninstall a Council waste water pump.

The main components are disassembled step by step, and hoisted to the loading dock. From there to be transported to the Intime workshop for refurbishment as part of an on-going scheduled maintenance programme.

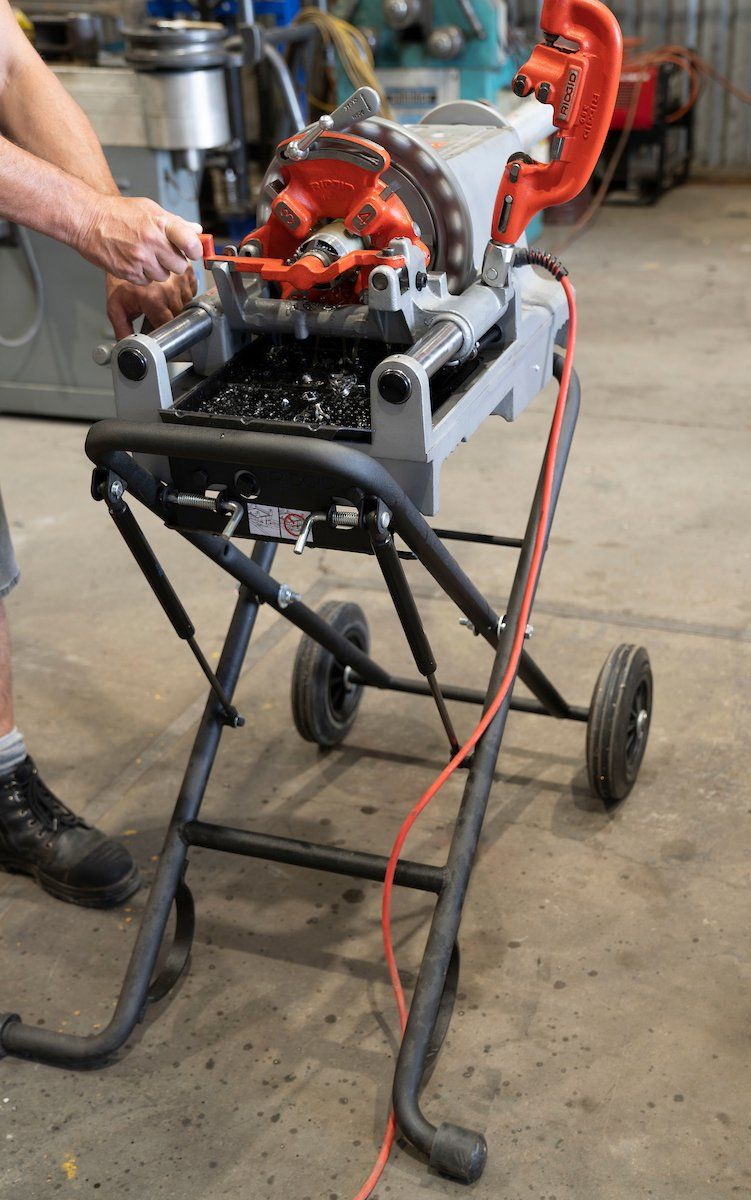

portable thread cutting machine

Investment in this portable thread cutting machine has enabled our engineers to increase the range of services that can be done on site. Threads can be cut in many configurations and materials enabling greater on-the-job flexibility.

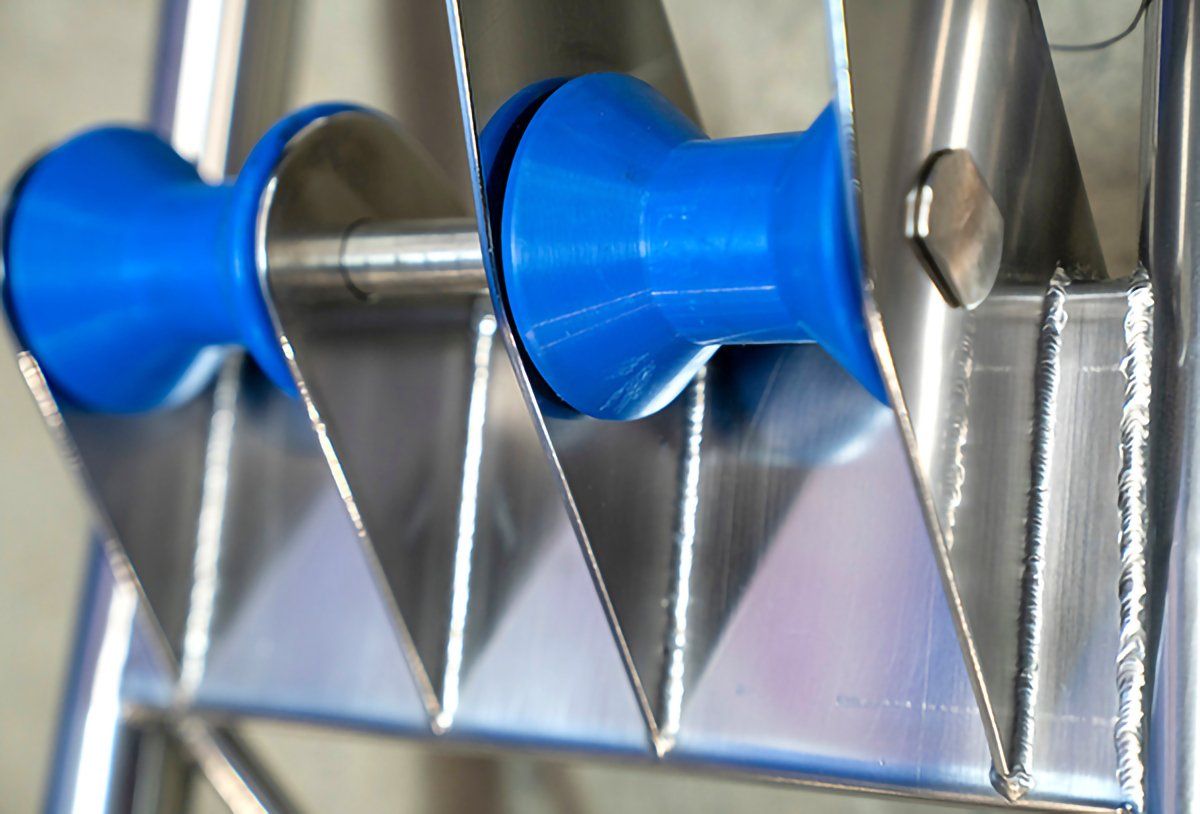

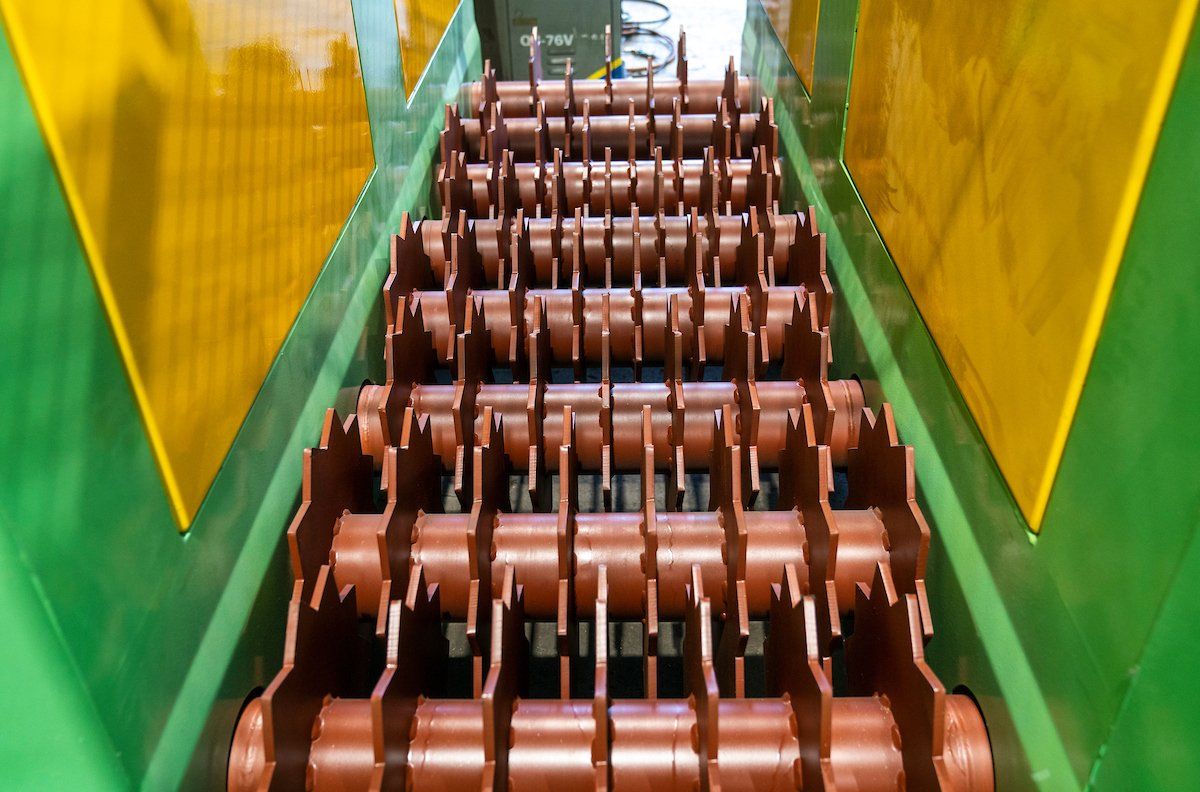

bark screen

View more

Intime have built a solid reputation in the forestry and sawmilling industry. Equipment has to be built to withstand the rigours of extra hard work and deliver continuous, rugged reliability.

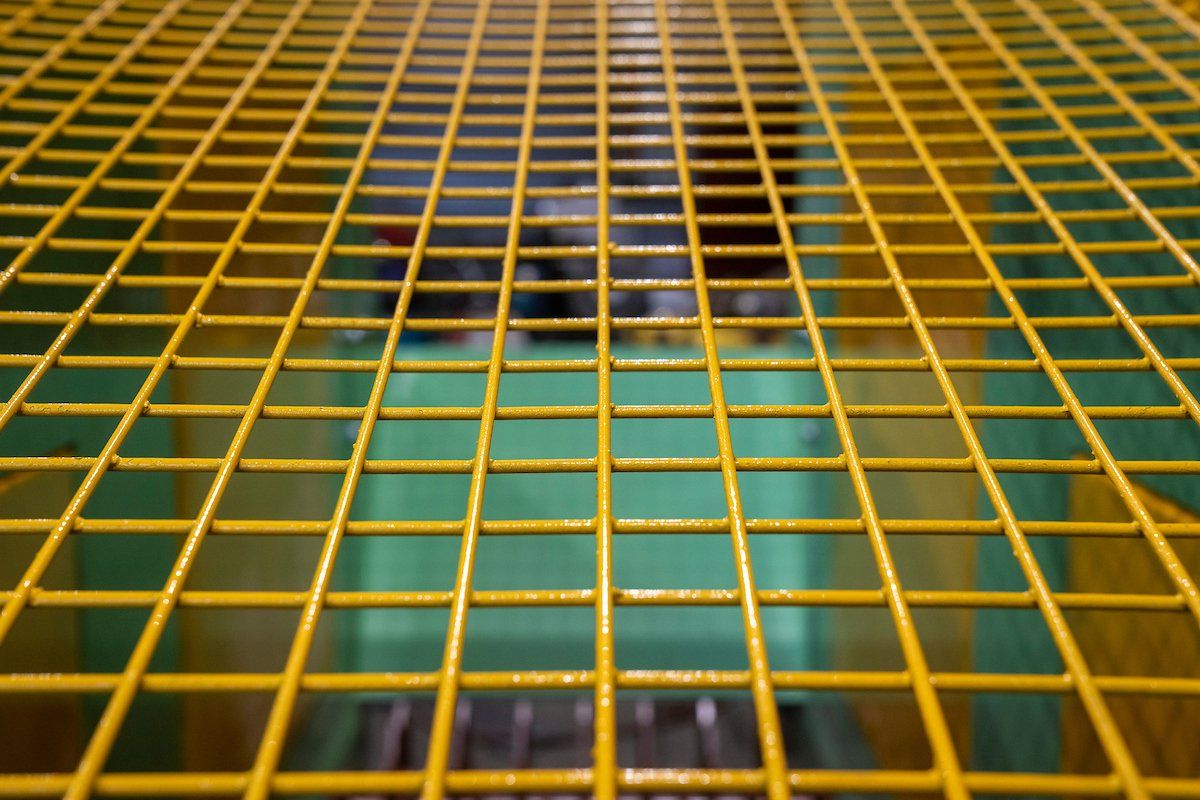

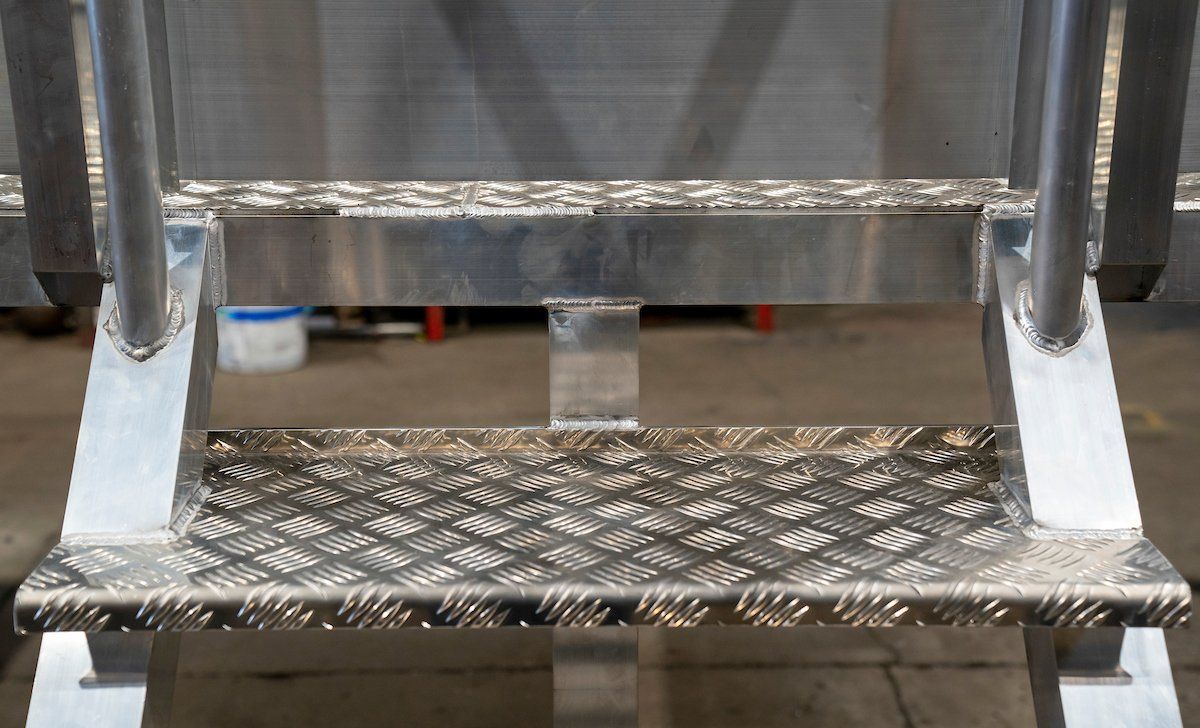

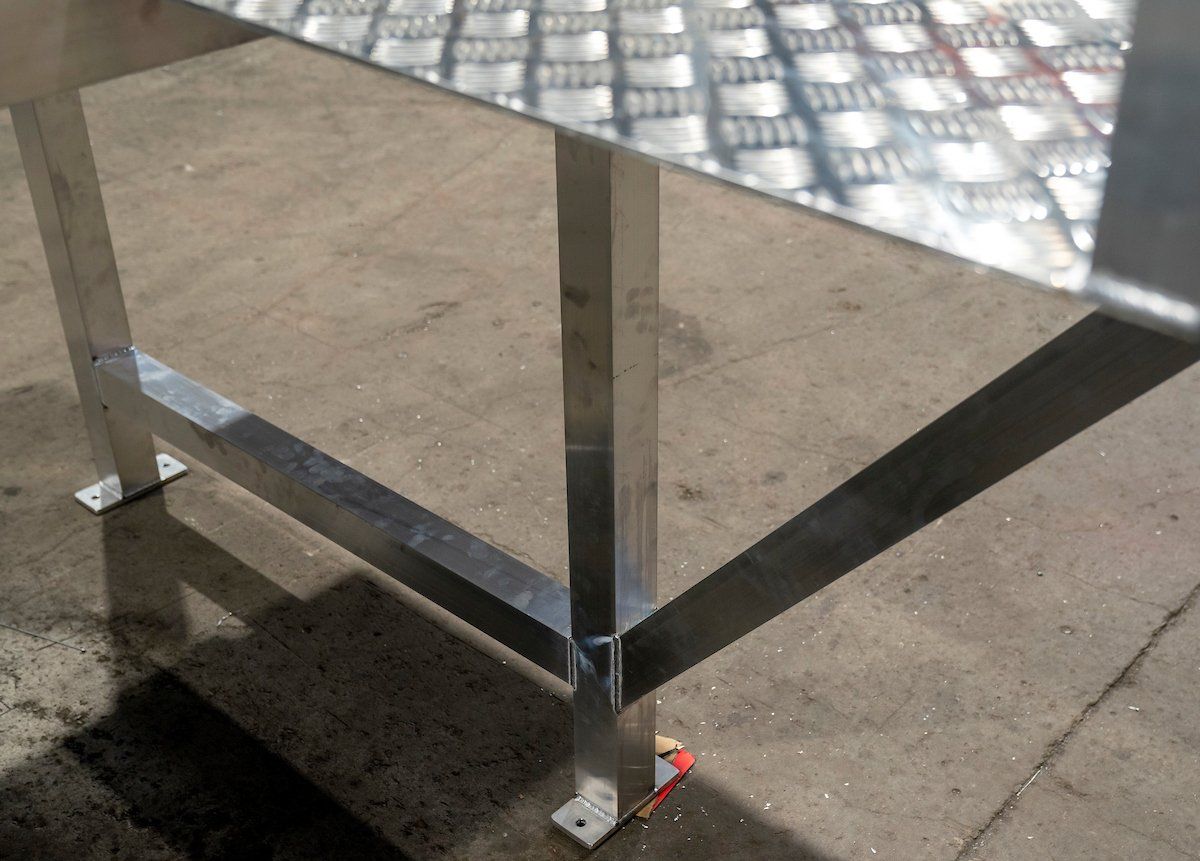

alloy platform

View more